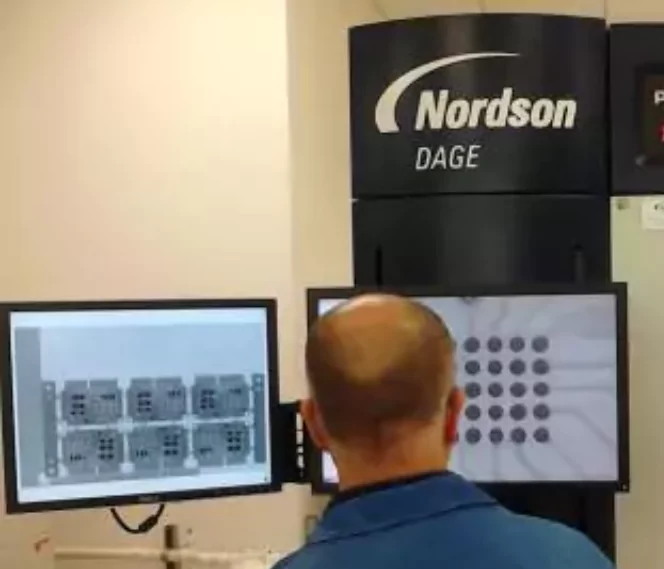

PCB assembly, printed circuit board assembly, PCB circuit board Ball Grid Array (BGA), and Chip Scale Packages (CSP) are extensively utilized in electronic devices. At our facility, we employ the Nordson DAGE Ruby X-ray and Nordson Quadra 5 X-ray Inspection Systems for ultra-high-resolution inspections in PCB assembly.

The X-ray Inspection System of choice:

Quadra™ 5 is the X-ray inspection system of choice for sub micron applications such as PCB and semiconductor package inspection, counterfeit component screening and finished goods quality control. The Nordson DAGE XD7600NT and Nordson Quadra 5 stand as exceptional machines designed for a comprehensive range of PCBA inspection tasks. These systems serve as invaluable tools aiding R&D engineers in diagnosing highly complex PCB assemblies, thereby accelerating the schedules of their development projects.

🛠️

The Most Powerful Tool for Engineers:

High Precision Inspection: Our ultra-high-resolution inspection capabilities ensure meticulous examination of PCB assembly components, including BGAs and CSPs.

R&D Support: These advanced inspection systems provide crucial support to research and development engineers, facilitating accurate diagnosis and swift progress in project timelines.